Blog Near-Net Shaping: Combining Shaping Technology with the Centrifugal Process

By: Dave Olsen

What is the Near-Net Shape Manufacturing Process?

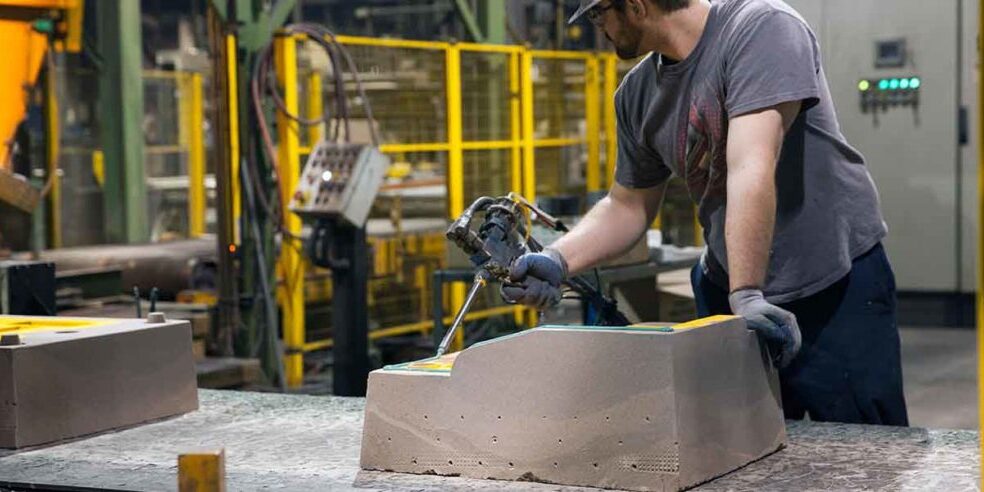

Near-net shaping combines various shaping technologies, such as sand casting and investment casting, with the high-integrity centrifugal process to maximize the benefits of each. Net-shaping can be readily added to add O.D. profiles to centrifugally cast components through the use of sand, ceramic, or split graphite dies. True net-shaping at investment casting levels of O.D. detail can be added by employing MetalTek’s proprietary net shaping technology and special tooling.

A key to this technology is the understanding of the physical metallurgical principles that control solidification. From a casting design standpoint, solidification modeling is frequently used to facilitate this understanding. Computer simulations of solidification, mold heat transfer, fluid dynamics, and particulate flotation are used to optimize critical parameters.

When to Use Near-Net Shaping

- In place of fabrications:

- Simplify: Reduces number of components.

- Cost savings: Eliminates welding.

- Cost Savings: Eliminates post-weld heat-treat.

- Quality: Improves quality of difficult to weld material.

- Speed: Increases speed of production.

- As an alternative to forged parts:

- Cost reduction: Reduces milling.

- Quality: Improved dimensional stability of a centrifugal.

- Speed: Shorter lead times / Increased speed of production.

- Design choices: Increased variety of alloy choices.

- As an alternative to conventional casting:

- Shaping: Combines the benefit of a static sand cast shaping while eliminating opportunity for mid-wall shrink.

- Welding: Smaller grain size compared to static sand casting improves weldability.

- Tooling: Mid-range tooling and castings pricing provides value for mid-short runs.

- Cost Savings: Compared to conventional centrifugals, reduces amount of metal to be poured, heat treated and machined away.

To learn more about this process or to determine if it is a fit for your application, please contact us.